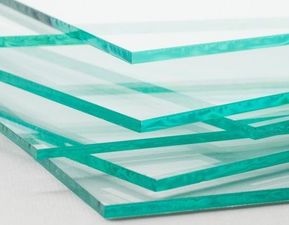

ANNEALED/FLOAT

Annealed glass is the most common glass used in windows, and is also known as float glass. Annealing is a process of slowly cooling hot glass objects after they have been formed, to relieve residual internal stresses introduced during manufacture. In larger or more complex products it commonly demands a special process of annealing in a temperature-controlled kiln, which is critical for durability. Glass that has not been properly annealed retains thermal stresses, which indefinitely decrease the strength and reliability of the product. Inadequately annealed glass is likely to crack or shatter when subjected to relatively small temperature changes or to mechanical shock or stress.

TEMPERED

Tempered glass is a type of safety glass processed by controlled thermal or chemical treatments to increase the strength compared with normal glass. Tempering puts the outer surfaces into compression and the inner surfaces into tension. Such stresses cause the glass, when broken, to crumble into small granular pieces (which are less likely to cause injury) instead of splintering into jagged shards such as plate glass. As a result of its safety and strength, toughened glass is used in a variety of demanding applications, including shower doors, patio doors, architectural glass doors and tables, passenger vehicle windows.

LAMINATED

Laminated glass is a type of safety glass that holds together when shattered. In the event of breaking, it is held in place by an inter-layer between its two or more layers of glass. The inter-layer keeps the glass bonded even when broken, and its high strength prevents glass from breaking into large sharp pieces. This produces a characteristic "spider web" cracking pattern when the impact is not enough to completely pierce the glass. Exterior storefronts and windows, skylight glazing and automobile windshields typically use laminated glass. Laminated glass is also used to increase the sound insulation rating of a window, where it significantly improves sound attenuation compared to non-laminated glass panes of the same thickness. For this purpose a special acoustic compound is used for the inter-layer.

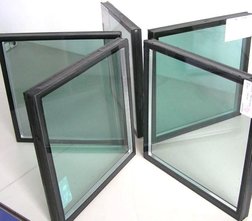

SEALED UNITS

Insulated glass (IG) sealed units are manufactured with glass that ranges in thickness from 3 to 10 mm (1/8" to 3/8") or more in special applications. Laminated or tempered glass may also be used as part of the construction. An insulated glass sealed unit is made with two panes of glass which are measured and cut to size, and separated with a spacer frame made from either tube or foam. The spacer is fixed onto the two panes of glass with a primary sealant, while a secondary sealant is applied to the back of the spacer to seal the unit. Insulated glass sealed units can also be gas filled to improve their thermal efficiency.

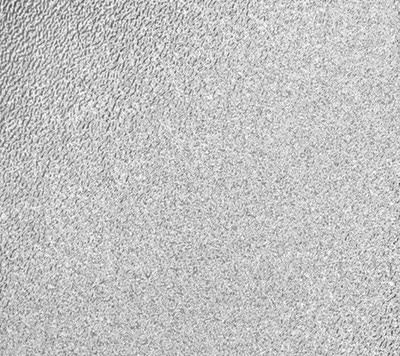

PATTERN

|

Rain

|

Reed

|

Pinhead

|

Satin-etch

|

Patterned glass is a kind of decorative glass with embossed patterns on one or both surfaces, generally used where privacy or obscurity is desired, though light transmission is still important. A wide range of textures and patterns offer both modern and contemporary designs, while making a subtle but confident statement. Mostly used in offices, bathrooms, cabinets and a range of decorative applications.

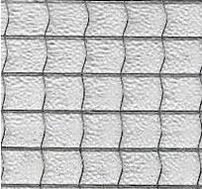

FIRE RATED

Georgian Polished Wire (GPW) is the most popular choice when it comes to fire-rated glazing solutions. Containing a wire mesh within the body of the glass, it offers reliable performance in a wide range of applications. GPW can contain fire and smoke, preventing or delaying them from spreading within a building. The wire holds the glass together when it breaks at high temperatures, unlike other fire-resistant glass types. You can find GPW glass in schools, public stairwells, fire escapes and the interior entrances to garages or parking structures.

Georgian Cast Wire (GCW) is an obscure glass you can't clearly see through, although it does transmit some light.

Georgian Cast Wire (GCW) is an obscure glass you can't clearly see through, although it does transmit some light.

POLYCARBONATES

Plexi - When compared with glass, plexi is generally described as more optically clear, impact resistant (up to 10 times stronger) and is half the weight of glass. Used in architectural glazing, large aquariums, and in heat-formed items such as curved windows in aircraft, it is considered a safer alternative to common glass in high risk areas. The main issue with plexi-glass are scratches and yellowing with age.

Lexan - A step up from plexi-glass, lexan does not crack or chip easily, is scratch resistant, and much easier to cut and drill. It is used in places where impact resistance is critical, such as safety lenses and police riot shields and visors.

Margard - Premium grade, hard-coated, high optical quality lexan, margard has a proprietary surface coating on one or both sides, providing a high level of resistance to abrasion and weathering, while maintaining UV protection of standard lexan. Available in 3 mm - 12 mm sheets, mainly used for building and vehicle safety and security glazing. Marketed as "virtually unbreakable", the only disadvantage being the high cost.

Lexan - A step up from plexi-glass, lexan does not crack or chip easily, is scratch resistant, and much easier to cut and drill. It is used in places where impact resistance is critical, such as safety lenses and police riot shields and visors.

Margard - Premium grade, hard-coated, high optical quality lexan, margard has a proprietary surface coating on one or both sides, providing a high level of resistance to abrasion and weathering, while maintaining UV protection of standard lexan. Available in 3 mm - 12 mm sheets, mainly used for building and vehicle safety and security glazing. Marketed as "virtually unbreakable", the only disadvantage being the high cost.